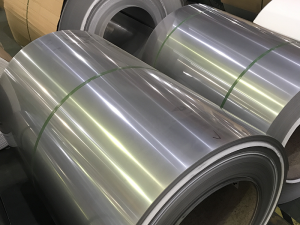

410S Coil Cruach Dhosmálta

Cur síos

Sonraíochtaí:

1.Standard: ASTM A240, JIS G4304, EN10088

2. Grád: 200sraith&300sraith&400sraith

3. Tiús: 0.03mm - 6.0mm

4. Leithead: 8mm-600mm

5. Fad: mar iarratas na gcustaiméirí

6. Dromchla: 2D, 2B, BA, Scáthán críochnaithe, N04, Líne Gruaige, bailchríoch Matt, 6K, 8K

7.Teicneolaíocht: fuar tarraingthe / fuar-rollta / rollta te

Ábhair:

| Cineál | Grád | Grád | Comhpháirt Cheimiceach % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Eile | |||

| Austéinít | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50 & 7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1. 4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1. 4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1. 4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1. 4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1. 4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1. 4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1. 4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1. 4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1. 4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1. 4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1. 4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1. 4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1. 4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1. 494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Déphléacsacha | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0. 035 | TI+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Eolas bunúsach

Coil Cruach Dhosmálta 410s, le friotaíocht maith creimeadh agus machinability, is cruach ginearálta agus cruach uirlis gearrtha é.Is cineál cruach é 410S is féidir feabhas a chur ar fhriotaíocht creimeadh agus ar fhoirmiúlacht 410 cruach. Is cruach ard-neart é 410S a fhéadfaidh friotaíocht creimeadh 410 cruach a fheabhsú tuilleadh.Úsáidtear é le haghaidh lanna tuirbín agus páirteanna teocht ard.

• Sonraíochtaí: AISI 410s, ASTM 410s

• Bailchríocha: Tá caighdeán dromchla den scoth ag dromchla Ba, dromchla 2b, Uimh.1 (craiceann bán), dromchla 2D, Uimh.4 (frosted), HL (líníocht sreang), dromchla 8K

• Tá feidhm ag lamháltais an mhuilinn ar thiús & maoile. Glaoigh ar JM Steel má theastaíonn méideanna sonracha nó treo gránach uait.

410S Teicneolaíocht meaisínithe tréith

1D - Tá cruth gráinneach neamhleanúnach ar an dromchla, ar a dtugtar dromchla ceo freisin.

Teicneolaíocht phróiseála: rollta te + lámhaigh annealing peening picling + rollta fuar + picilte annealing.

2D - Dath bán beagán airgid.

Teicneolaíocht phróiseála: rollta te + lámhaigh annealing peening picling + rollta fuar + picilte annealing.

2B -- Silver bán le snasta agus maoile níos fearr ná dromchla 2T.

Teicneolaíocht próiseála: rollta te + lámhaigh annealing peening picilte + rollta fuar + annealing picilte + múchadh agus faghartha rollta.

Ba - Snasta dromchla den scoth, frithchaiteacht ard, cosúil le dromchla scátháin.

Teicneolaíocht próiseála: rollta te + lámhaigh annealing peening picilte + rollta fuar + picilte annealing + snasta dromchla + múchadh agus faghartha rollta.

Uimh.3 -- Snasta maith, dromchla grán garbh.

Teicneolaíocht phróiseála: rollta snasta agus faghartha do 2D nó 2B le 100 ~ 120 ábhar scríobach (JIS R6002).

Uimh.4 -- Snasta maith, línte míne ar an dromchla.

Próiseas próiseála: rollta snasta agus faghartha le haghaidh 2D nó 2B le 150 ~ 180 ábhar scríobach (JIS R6002).

HL -- Liath airgid le stríoca gruaige.

Teicneolaíocht phróiseála: Is gráin scríobach leanúnach é táirgí 2D nó táirgí 2B le gráinneacht chuí na n-ábhar scríobach chun an dromchla a snasú.

MIRRO -- Specular.

Teicneolaíocht phróiseála: Táirgí 2D nó táirgí 2B le granularity cuí an ábhair mheilt a mheilt agus a snasú go dtí an éifeacht scátháin.